This article takes you to understand the difference between PCB and PCBA

When learning PCB design, we often encounter two concepts with very similar names, namely: PCB and PCBA. Everyone knows that PCB is a printed circuit board, so what is PCBA? What are the connections and differences between them?

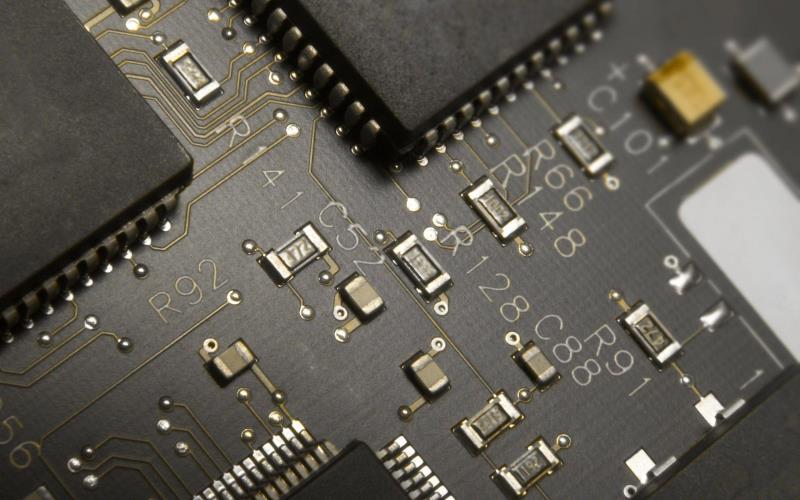

About PCB

PCB is the abbreviation of Printed Circuit Board, translated into Chinese is called printed circuit board, because it is made by electronic printing, it is called "printed" circuit board. PCB is an important electronic component in the electronics industry, a support for electronic components, and a carrier for electrical connection of electronic components. PCB has been extremely widely used in the manufacture of electronic products. The unique characteristics of PCB are summarized as follows:

1. The wiring density is high, the volume is small, and the weight is light, which is conducive to the miniaturization of electronic equipment.

2. Due to the repeatability and consistency of the graphics, it reduces wiring and assembly errors and saves equipment maintenance, debugging and inspection time.

3. It is conducive to mechanization and automated production, which improves labor productivity and reduces the cost of electronic equipment.

4. The design can be standardized to facilitate interchangeability.

About PCBA

PCBA is the abbreviation of Printed Circuit Board + Assembly, which means that PCBA passes through the entire manufacturing process of PCB blank board SMT and then DIP plug-in.

Note: SMT and DIP are both ways to integrate parts on the PCB. The main difference is that SMT does not need to drill holes on the PCB. In DIP, the PIN pins of the parts need to be inserted into the holes that have been drilled.

SMT (Surface Mounted Technology) surface mount technology mainly uses mounters to mount some tiny parts on the PCB. The production process is: PCB board positioning, solder paste printing, mounter mounting, and reflow Furnace and finished inspection.

DIP stands for "plug-in", that is, inserting parts on the PCB board. This is the integration of parts in the form of plug-ins when some parts are larger in size and are not suitable for placement technology. The main production process is: sticking adhesive, plug-in, inspection, wave soldering, printing and finished inspection.

The difference between PCB and PCBA

From the above introduction, we can know that PCBA generally refers to a processing process, which can also be understood as a finished circuit board, which means that PCBA can only be counted after the processes on the PCB board are completed. The PCB refers to an empty printed circuit board with no parts on it.

In general: PCBA is a finished board; PCB is a bare board.