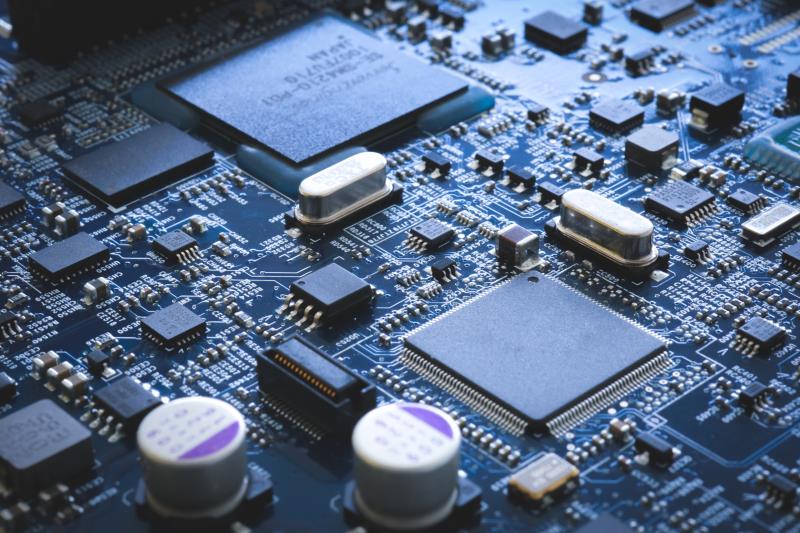

Via hole has the effect of interconnection and conduction of lines. The development of the electronics industry also promotes the development of PCB, and also puts forward higher requirements on the manufacturing process of printed circuit boards and surface mounting technology. Via hole plugging technology came into being, and should meet the following requirements together:

Causes of PCB plugging oil

2. There must be tin and lead in the via hole, with a certain thickness requirement (4 microns), and no solder mask ink should enter the hole to form the hole with tin beads; the realization of the conductive hole plugging process

Regarding the surface mounting board of the circuit board, especially the mounting of BGA and IC, the via hole plug must be flat, convex and concave plus or minus 1 mil, and there must be no red tin on the edge of the via hole; the via hole hides the tin beads, In order to meet the requirements of customers, the via hole plugging process can be described as various, the process is particularly long, the process is difficult to control, often there are problems such as oil drop during hot air leveling and green oil solder resistance test; oil explosion after curing. Based on the actual production conditions, the various plugging processes of PCB are summarized, and some comparisons and discussions are made in the process and advantages and disadvantages:

Note: The working principle of hot air leveling is to use hot air to remove the remaining solder on the surface and holes of the printed circuit board, and the remaining solder is evenly coated on the pads, non-resistive solder lines and external packaging points, which is the surface treatment of the printed circuit board One of the ways.

1. Hole plugging process after hot air leveling

The process flow is: board surface solder mask→HAL→plug hole→curing. The non-plugging process is used for production. After the hot air is leveled, the aluminum screen or the ink blocking screen is used to complete the via hole plugging required by the customer. The plug hole ink can be photosensitive ink or thermosetting ink. In the case of ensuring the same color of the wet film, the plug hole ink is best to use the same ink as the board surface. This process can ensure that the through holes will not lose oil after the hot air is leveled, but it is easy to form a plug hole ink to contaminate the board surface and be uneven. It is easy for customers to form false soldering during mounting (especially in BGA). Therefore, many customers do not accept this approach.

2. Hot air flattening the front plug hole process

2.1 Use aluminum sheet to plug the hole, solidify, and grind the board for graphic transportation

This process uses a CNC drilling machine to drill the aluminum sheet that needs to be plugged into a screen, and plug the holes to ensure the fullness of the via hole plugging. The plug hole ink plugs the hole ink, and the thermosetting ink can also be used. Its characteristics have the necessary hardness. Large, the resin shortens and changes little, and the bonding force with the hole wall is good. The process flow is: pre-treatment → plug hole → grinding plate → graphic handling → etching → board surface solder mask.

This method can ensure that the plug hole of the via hole is flat, and the hot air leveling will not cause quality problems such as oil explosion and oil drop on the edge of the hole. However, this process requires one-time thickening of copper to make the copper thickness of the hole wall reach the customer's standard. Therefore, the requirements for the copper plating of the whole plate are very high, and the functions of the plate grinding machine are also very high, to ensure that the resin on the copper surface is completely removed, and the copper surface is clean and not contaminated. Many PCB factories do not have a one-time thickening copper process, and the function of the equipment does not meet the requirements, which constitutes that this process is not used much in PCB factories.

2.2 After plugging the hole with aluminum sheet, directly screen-print the board surface solder mask

This process uses a CNC drilling machine to drill out the aluminum sheet that needs to be plugged to make a screen, install it on the screen printing machine for plugging. After the plugging is completed, it should not be parked for more than 30 minutes, and the 36T screen is used to directly screen the surface of the board. The process flow is: pre-treatment-plug hole-silk screen-pre-baking-exposure-development-curing.

This process can ensure that the via hole is well covered with oil, the plug hole is flat, and the wet film color is consistent. After the hot air is leveled, it can ensure that the via hole is not tinned, and the hole does not hide tin beads, but it is easy to form the ink in the hole after curing. The soldering pads constitute poor solderability; after the hot air is leveled, the edges of the vias bubbling and oil is removed. It is difficult to use this process to control production. The process engineers must select special processes and parameters to ensure the quality of the plug holes.

2.3 The circuit board aluminum sheet is plugged into the hole, developed, pre-cured, and the board surface is soldered after the board is polished.

Use a CNC drilling machine to drill out the aluminum sheet that requires plugging holes to make a screen, install it on the shift screen printing machine to plug the holes, the plug holes must be full, and the two ends are better, and then solidify and polish the board for surface treatment. The process flow is: pre-treatment-plug hole-pre-baking-development-pre-curing-board surface solder resist.

Because this process uses plug hole solidification to ensure that the via hole does not lose oil or explode after HAL, but after HAL, it is difficult to completely solve the problem of tin bead in the via hole and tin on the via hole, so many customers do not accept it.

2.4 The solder mask on the surface of the circuit board is completed with the plug hole.

This method selects 36T (43T) screen, installs it on the screen printing machine, selects a backing plate or a nail bed, and plugs all the through holes together with the circuit board surface. The process flow is: pretreatment-silk screen printing -Pre-baking-exposure-development-curing.

The process time is short and the equipment utilization rate is high. It can ensure that the via holes will not lose oil after the hot air leveling, and the via holes will not be tinned. However, due to the selection of silk screen for plugging, there is a lot of air in the via holes. , The air expands and breaks through the solder mask, forming a cavity and unevenness. There will be a few via holes to hide tin in the hot air leveling. Now, our company has passed many tests, selected different types of inks and viscosity, adjusted the pressure of the screen printing, etc., and basically solved the voids and unevenness of the vias. This process circuit board has been selected for mass production.

3. The through holes must have solder mask ink plug holes, opaque, and must not have tin rings, tin beads, and flatness requirements.

With the development of electronic products in the direction of "light, thin, short, and small", PCBs are also developing with high density and high difficulty. Therefore, many SMT and BGA PCBs are presented. However, customers require plug holes when mounting components. There are mainly five Effects:

1. Prevent the tin from passing through the via hole to the component surface to form a short circuit when the PCB is wave soldered; especially when we put the via hole on the BGA pad, it is necessary to make a plug hole first, and then plate it with gold, which is convenient for BGA soldering;

2. Prevent the flux residue from remaining in the via hole;

3. Prevent the tin beads from popping up during wave soldering and forming a short circuit;

4. Prevent the external solder paste from flowing into the hole to form a virtual solder, which affects the placement;

5. After the surface mounting of the electronics factory and the assembly of the components are completed, the PCB must be vacuumed to form a negative pressure on the testing machine to complete.